Plastering plaster

It is a general term for a type of mortar that is applied to a building substrate to level or provide protection. It is mainly composed of cementitious materials, fillers and a variety of functional additives.

1. Cementitious materials: gypsum powder, lime, cement

2. Fillers: glass beads, heavy calcium powder, fine sand, etc.

3. Auxiliary materials: cellulose ether, retarder, air entraining agent, starch ether, etc.

(1) Main cementitious material: gypsum powder

The main cementitious material in plastering gypsum is gypsum powder. It is a lightweight material, and the amount added affects the coating rate of the mortar (a high content results in a relatively high coating rate). If the proportion is too low, it will result in low mortar strength and powder shedding; however, the proportion should not be too high, as this will increase costs and affect the mortar’s cement-to-sand ratio, which may result in cracking.

(2) Main lightweight aggregate: glass beads

The amount of glass beads added is determined mainly by the quality, strength and quantity of the gypsum powder in the plastering gypsum. The higher the amount added, the higher the water demand, bulk density and coating rate of the mortar, while the flexural and compressive strengths of the mortar will decrease accordingly. Therefore, considering the quality and cost of the plastering gypsum, we should choose glass beads of the following qualities:

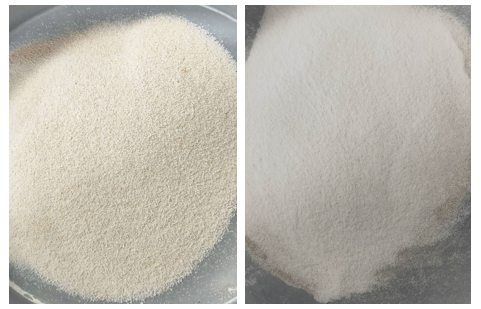

1. Appearance: good shape, good uniformity and less dust, so the strength will be relatively high;

2. Density: The general capacity of glass beads is 100-120kg/m³. If the density is too low, the strength of the mortar will be low; if the density is too high, the coating rate of the mortar will be reduced, thereby increasing the overall cost of the mortar.

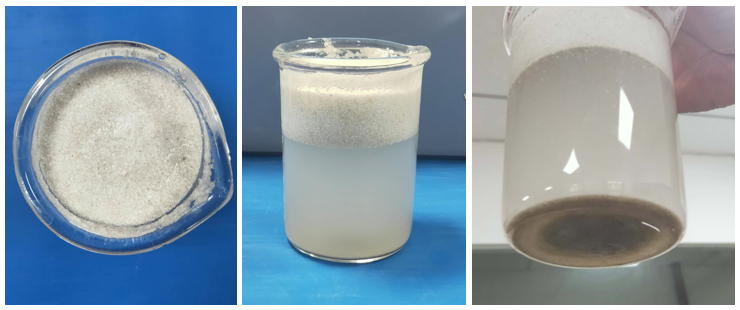

3. Water absorption: Under the same conditions of quantity, water volume and soaking time, the more glass beads float, the better the quality.

(3) Main fillers: ground calcium carbonate powder and fine sand

Ground calcium carbonate powder and fine sand are commonly used and stable aggregates in plastering gypsum. They not only improve the workability and coating rate of the mortar, but also further improve the flexural and compressive strength of the mortar. However, attention should be paid to the mixing ratio of the cementitious material and them, otherwise problems such as powder loss and cracking may occur.

According to experimental testing, with other conditions remaining unchanged, changing the mixing ratio of ground calcium carbonate powder and fine sand leads to the following conclusions:

1. Water demand: will increase with the increase of the amount of fine sand added;

2. Bulk density: will first increase to a certain level and then decrease with the increase of the amount of fine sand added;

3. Flexural and compressive strength: will first increase to a certain level and then decrease with the increase of the amount of fine sand added.

(4) One of the main additives: cellulose ether

As a major rheological modifier, cellulose ether can have the following effects on the performance of plastering gypsum:

1. It can improve the consistency of the mortar and also increase the water demand of the mortar;

2. It can effectively retain the moisture in the mortar, thereby helping to improve the flexural and compressive strength of the mortar;

3. As a thickener, it has the effect of inducing and stabilizing bubbles, thereby increasing the bulk density of the mortar.

(5) One of the main auxiliary materials: retarder

An essential auxiliary material in plastering gypsum is the gypsum retarder, which is mainly used to reduce the setting speed of gypsum, give the mortar sufficient initial and final setting times, facilitate construction and improve strength. The amount added will be affected by the following factors:

1. The initial setting time of the gypsum powder itself: The initial setting time of desulfurization gypsum and phosphogypsum is generally 5-10 minutes, while that of natural gypsum is longer. According to experimental tests, for every 1-minute difference in the initial setting time of gypsum powder, there will be a 10-20-minute difference in the initial setting time after the addition of retarder. Therefore, when developing and upgrading products, it is recommended that a unified standard be used to test the initial and final setting times of gypsum powder after the addition of retarder in order to stabilize product quality.

2. Anhydrous AⅢ content: This is an active substance with a setting-promoting effect. As the storage time increases, it will prolong the initial setting time of the gypsum powder, which will make it difficult to determine the amount of retarder to add, thus affecting the production of plaster gypsum and even causing the risk of mortar cracking. Therefore, it is recommended to choose gypsum powder that has undergone effective aging and has stable performance to produce plastering mortar, and to do a good job of quality inspection of the initial setting time of each batch to further reduce the risk.

3. Content of dihydrate: This substance can reduce the retarder’s retardation effect and even render the retarder useless, resulting in problems such as low strength and powder loss.

4. Effect of mortar pH: Retarders generally achieve maximum benefit in neutral or slightly alkaline environments.